News

Here are some latest technology showcases from Siemens

2017-09-05

Siemens: Siemens in this session of the EMO theme is "machine digital manufacturing." As we all know, Siemens has invested a lot of resources in the field of digitalization in recent years and has made a lot of achievements as a soft and hardware supplier in the field of machine tools and a high degree of integration in the machine tool industry, as Dr. Heuring, Global CEO of Siemens Motion Control "Digitalization will allow the entire machine tool industry to continue to move forward and make it change faster.Through the digital virtual world and the real world docking can achieve a significant increase in production efficiency and can make more new business model to become It is possible, regardless of whether the size of the customer is large, medium or small, not only for machine tool manufacturers, but also for users of machine tools, which has become the core of business growth and profitability in the German and foreign machine tool industries.

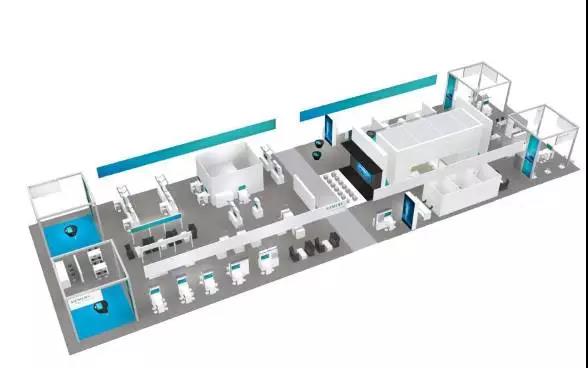

Based on this, the EMO show in 2017, Siemens will show a series of "from a single machine to the factory management," the seamless connection of digital solutions. Which will be in our 1200 square meters of booth for everyone to show.

What new products are emerging at Siemens in this exhibition?

Siemens: We will showcase new hardware solutions during the show, such as in order to make our SINUMERIK OPERATE operating system more efficient, we will launch a new 16: 8 touch widescreen display, machine Manufacturing can be based on the standard interface and then add some of their own secondary development, the characteristics of the additional interface and the two integration in one.

As for the software function, "anti-collision check function", "pitch compensation function" for the end of the machine introduced a corresponding solution. And ultimately help our machine tool builder improve machine performance and improve the reliability of complex parts. For high-end CNC machine tools, we have introduced a new safety integrated solution (Safety Integrated Plus), while ensuring the safety function of the original machine at the same time, the relevant safety function design and debugging time can be effectively reduced by more than 20%.

Especially for the "digital" theme, I believe that many fans must be very interested in the relevant solutions, whether for us ahead of "spoilers" look?

Siemens: The significance of digital solutions is that it can connect to the entire manufacturing process of the virtual part (design phase) and the real part (production stage), and Siemens can provide to the production operations management (MOM), Simatic IT, CNC solutions SINUMERIK) and the Automated Control System (Simatic S7), the main contents of this exhibition are the following:

• "Digital Twins": Siemens will showcase digital solutions to machine builders and end customers at this show. Visitors to the booth will see our "digital twins" in this way Can help machine tool manufacturers to significantly save the machine design and commissioning time, improve production flexibility and efficiency, and ultimately can make the machine tool products can be more efficient design out;

• "Manage MyMachines" App (App): Another highlight of this exhibition is based on the "MindSphere" cloud platform, for the machine tool industry Internet of Things (IoT) operating system APP "Manage MyMachines", at the show will be 200 Taiwan machine through this APP to achieve the connection, the user can through this platform can get some important machine running data and the operation of all machine tools. So that the management of the factory can be timely and clear understanding of the workshop production and operation.

• Sinumerik Edge: Sinumerik Edge can use the Sinumerik Edge to monitor the entire machining process and process of the machine at the machine side while ensuring the safety of the entire data acquisition process. For the collected data, You can process a certain analysis and optimization, and then can upload data to the host computer. In addition to the relevant hardware equipment, Siemens also provides the relevant App to better complete the process data monitoring and optimization of work; machine manufacturing can also be based on an open architecture to develop their own characteristics App.