Tech support

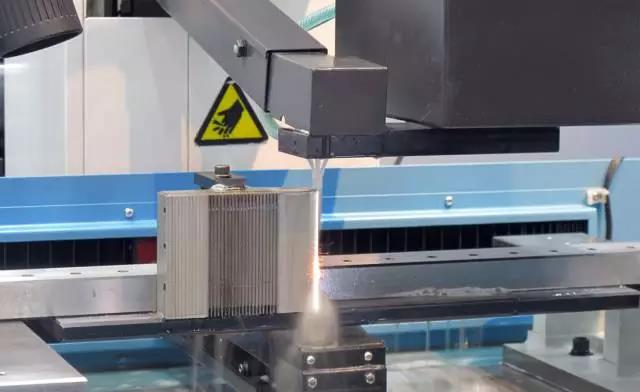

How to enviromentally friendly deal with waste water of wire EDM cutting?

2017-09-05

Recently, the state is increasingly demanding environmental protection, more and more strict. In the establishment of the National Environmental Inspectorate and rectification determination, the whole coastal, "Pearl River Delta" and "Yangtze River Delta" as the representative of thousands of water, gas, printing and dyeing, metal processing plants, manufacturing or move away Collapse, forcing enterprises to upgrade.

As early as 1998, the State Environmental Protection Administration, the State Economic and Trade Commission, the Ministry of Foreign Trade and Economic Cooperation and the Ministry of Public Security under the "People's Republic of Solid Waste Pollution Prevention Law", developed a "national list of hazardous waste", which clearly stipulates waste soap, Emulsified oil / water, hydrocarbon water mixture, emulsion cream cutting agent for hazardous waste. So the old cutting fluid cutting fluid emulsified oil, must be subject to professional treatment, guidance counseling treatment, in order to discharge.

I am engaged in wire cutting EDM environmental protection industry for more than 20 years, combined with the European Union, Japan, Chinese and foreign enterprises, industrial areas around the environmental requirements of experience, is now fast, in the wire machine processing and discharge of the relevant experience of the share to you, hope Business owners in the process of creating the value of wealth, commitment to the process of social responsibility, reduce the blind spot, detours, from fine to shut down.

1. Selection of processing fluid

First of all to choose the real green water line cutting fluid. The real green environmental processing fluid must not contain sodium nitrite, silver nitrite, six potassium chromium, heavy metals and other harmful substances and pollution sources. Most of the "water" cutting fluid on the market is a "semi-synthetic water-soluble oil" that contains a lot of non-standard mineral oil, which is not really green green processing fluid.

We in the actual processing and production, to do:

1) standard use, strict change of water to add;

2) to create conditions for centralized liquid, the old liquid uniform; concentrated liquid can improve the utilization of working fluid and processing efficiency, to maintain the stability of the working fluid, to maintain a good cooling, chip action.

3) concentration management;

4) regular care, diluted after three waste detection.

2. Machine cleaning system cleaning system

We in the actual processing and production, the old liquid contains a lot of molybdenum, iron, toner, sludge and other metal mixed powder and impurities, while the water tank dead ends and pipes, pump inside the filter also accumulated a certain amount of metal powder and debris The Therefore, the tank, the table and the pipeline for thorough, adequate cleaning, two intervals of 30 minutes (interval is a sterilization time), each time 10 minutes required cleaning.

Cleaning method:

1) can be added with water plus detergent, open the pump cycle 0.5 hours.

2) with industrial cleaning agent 5%, "machine cycle system fungicide 0.2%" dissolved in 100% of the water, the winter is heated with no less than 60 degrees of water cleaning, open the pump cycle 0.5 hours, wash twice.

3. Nonwovens filter

Filter out solid waste:

1) the old liquid with non-woven filter, relying on the gravity of the liquid through the non-woven fabrics, isolation sludge and other debris.

2) can filter out the sludge, solid particles.

3) conditional users can buy a portable oil filter, the old liquid twice filtered.

4) filtered out of the sludge, solid particles concentrated in full bloom.

5) Assuming 300 kg of the old liquid, about 60 kg of particulate matter and sludge can be filtered out after two passes.

6) According to the solid waste treatment specifications, particulate matter and sludge solid waste, installed nylon bag, classified garbage disposal.

4. Add settling agent precipitation

Assuming 300 kg of the old liquid, the remaining 240 kg of liquid remaining in the previous step:

1) by the supplier (such as Mold Germany Petrochemical) to join the total amount of 2% to 5% sedimentation adsorbent and environmentally friendly activated carbon agent, moderate stirring after precipitation.

2) can also be adsorbed with sea sand, with the agent into a light-colored liquid;

3) moderate mixing, precipitation once, precipitation repeated 1,2 once again, will produce semi-fluid, semi-solid waste, about 60 kg.

4) open iron cans placed "semi-fluid, semi-solid waste" 3-6 months later, about 40 kg of water dry after evaporation, resulting in about 20 kg of solid waste particles, and then install the nylon bag, according to classified waste disposal, According to solid waste.

5. Dilution and discharge

Finally, now the remaining 180 kg of liquid, add 10 times the water that is 1900 kg diluted. Almost no pollution, diluted liquid can be directly discharged; can also be used for recycling online processing of liquid in the secondary use, can also be industrial floor washing, toilet sanitary ware cleaning.

Author: Zhao Xiaojun, China Die & Mold Industry Association; China special processing electric processing branch expert members; Ningbo Shaanxi Chamber of Commerce vice president, city machine tool association director, international equipment lubrication association, Shanghai lubricants association expert member; Zhejiang mold German petrochemical limited General manager of the company.